idt

instrument design technology

Beamline Engineering Excellence

Monochromator Stability

The stability of a monochromator is the most important factor in beamline performance.

IDT have invested great effort into ensuring our range of monochromators are exceptionally

stable, allowing the full potential of beamline performance to be realised. This

page outlines how we approach DCM stability and demonstrates the exceptional performance

achieved on the air-

54 nrad Measured Beamline Stability

The stability of the IDT-

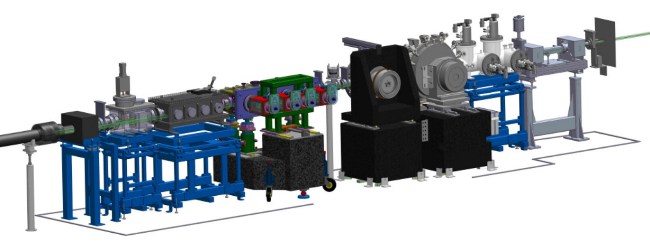

The beamline consists of a primary slit system, an air-

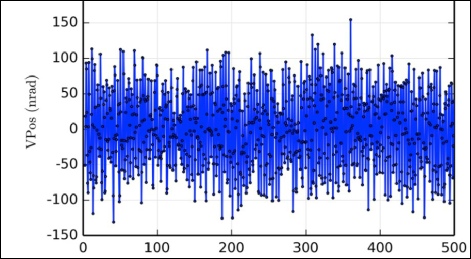

Beam energy at 7.2 keV, no active feedback, sampling position every 0.5 sec for 500 sec.

BPM vertical position is recorded and converted to an angle. The vibrations observed are the net effect from the source, DCM and double mirror system.

Standard deviation of beam angle: 54 nrad

BPM Vertical Position

Click to enlarge

Beam position monitor (~43m)

Double horizontal mirror system (~32m)

Air bearing DCM (~28m)

Canted primary slit system(~25m)

GSECARS Beamline Layout:

Also see our pages on the upgraded GSECARS beamline and air-

IDT adopt a unique thermal isolation approach in monochromator design to minimise thermal drift and maximise stability in the mechanics.

Thermal drifts in monochromators can result in a dramatic loss of beam intensity and stability. The thermal stability of the mechanics is a crucial factor in the performance of any monochromator.

Vibrations from water flow in cooling circuits, which are often used to thermally stabilise monochromator mechanics, can introduce further instabilities into the beam.

Our approach involves thermally isolating all components subjected to temperature fluctuations (crystals, motors etc) from the monochromator mechanics, and removes the need for water stabilisation circuits or heaters.

Point contacts, thermal insulators and machined thermal barriers are used throughout

the monochromator design to provide multi-

A well engineered crystal cooling system is crucial to monochromator performance.

Efficient cooling of the heat-

IDT monochromators feature crystal cooling schemes designed and engineered for the specific beam profile and heat load from the source of the beamline. Thorough design & FEA studies are carried out to determine the optimal cooling design for each individual monochromator.

For insertion device monochromators IDT can offer vibration-

For bending magnet monochromators IDT have developed a direct water cooling system which can be adapted to the specific bending magnet beam profile.

Above: Direct Water Cooled Crystal, featuring cooling hole pattern designed to match the beam profile giving optimum cooling over the entire bragg angle range.

Above: Cryo-

Cooling Techniques

Proven Thermal Isolation Approach

Minimising the transmission of vibration from motors, cooling lines and external sources to the crystals is critical to monochromator stability.

Our design philosophy of low mass, high stiffness components leads to very stable devices with high natural frequencies.

We have developed proven cooling schemes specifically engineered to minimise the transmission of vibrations from the cooling lines to the optic.

We have also developed a proven method of isolating a monochromator from external environmental vibrations, using viscoelastic dampers in the monochromator support system.

This approach has yielded a measured beamline stability of 54 nrad on GSECARS at the APS (see above).

Vibration Isolation & Mitigation

Granite base block

Viscoelastic damper

Adjustable wedge